"*" indicates required fields

Overview

This course catalog serves to outline the educational materials currently offered by the IAAE®. The IAAE® offer educational materials that are product agnostic and not training materials that have a focus on specific products and platforms. Courses shown do not need to be taken in a specific sequence, and it is highly unlikely that any one individual would benefit from taking all materials offered. The IAAE® recommend an individual

development plan be created for each participant and that a group of participants engage in a coordinated program over either eight or twelve months.

At the moment, there are five IAAE® courses available, containing various modules within each that cover a wide range of topics.

Every module has specific aims and learning objectives, described in detail in this catalog, which shed light on the overall content within each and help one understand the target audience.

click on a section on the left to quickly navigate this catalog

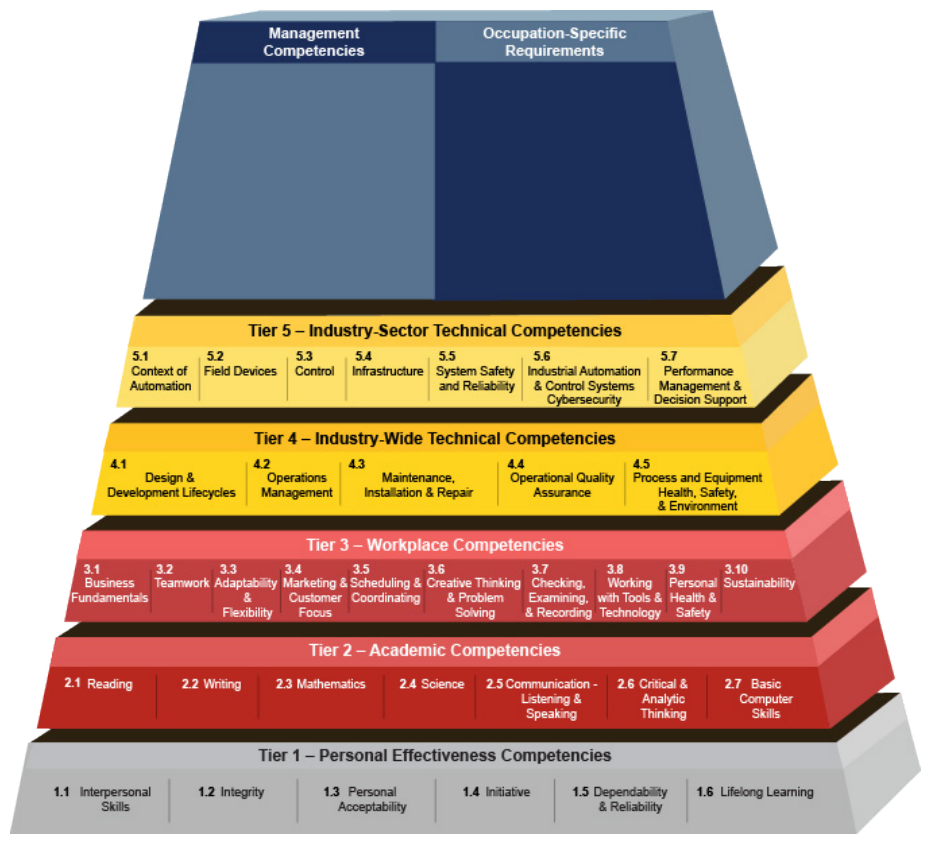

The modules developed by the

IAAE® within this online course fully align to Tier 5 – Industry-Sector Technical Competencies within the Automation Competency Model (pictured and described in the next two pages) developed by the US Dept.

of Labor, Employment and Training Administration, with input from the Automation Federation.

The 37 online modules within the course (approximately 3 hours seat time each) cover the topics within the Tier 5 subject areas as pictured on the next page.

These online materials have already been reviewed by senior automation SMEs within Merck and Genentech and have also received very positive feedback from many of the participants at GSK, Takeda, Biogen, and other organizations.

For more information on this model follow this link

The Automation Competency Model is a resource that provides a comprehensive collection of the competencies – the knowledge, skills, and abilities – required in the automation industry. The competencies are described using examples of the critical work functions and the technical content common to the industry. A competency describes a behavior but does not describe a level of performance, as different workers will need different levels of competence to complete their job functions.

The model is depicted in a graphic consisting of several tiers. Each tier is comprised of blocks that group the knowledge, skills, and abilities essential for successful performance in the industry. At the base of the model, the competencies apply to a large number of occupations and industries. As a user moves up the model, the competencies become industry- and occupation-specific. The pyramid shape does not imply that competencies at the top are at a higher level of skill. Instead, the model’s shape represents the increasing specialization and specificity in the application of skills.

Tiers 1 through 3, called Foundation Competencies, form the foundation needed to be ready to enter the workplace.

Tier 1 – Personal Effectiveness Competencies represent personal attributes or “soft skills”. Essential for all life roles, personal effectiveness competencies are generally learned in the home or community and reinforced at school and in the workplace.

Tier 2 – Academic Competencies are critical competencies primarily learned in a school setting. They include cognitive functions and thinking styles, and are likely to apply to most industries and occupations.

Tier 3 – Workplace Competencies represent motives and traits, as well as interpersonal and self-management styles honed in the workplace. They are generally applicable to a large number of occupations and industries.

Tiers 4 and 5 show the cross-cutting industry-wide technical competencies needed within an industry wherein a worker can move easily across industry sub-sectors. Rather than narrowly defining a single occupational career ladder, this model supports the development of an agile workforce.

Tier 4 – General Technical Competencies represent the basic knowledge and skills that are common across automation sectors.

Tier 5 – Specific Technical Competencies represent advanced competencies that are specific to automation. The upper tiers represent the occupational specialization within the industry.

Section A: Context of Automation (Module 010)

Module: 010

Introduction to automation for Life Sciences manufacturing

This introductory module aims to introduce you to automation for Life Sciences manufacturing by asking:

Section B: Measurement, Sensors, and Actuation (Modules 020-070)

Module: 020

Basic Process Instrumentation

This module aims to give you an introduction to measurement and basic process instrumentation. The learning objectives of this module are that you will be able to explain measurement of:

Module: 030

Analytical Instrumentation

This module aims to give you an introduction to the purpose of analytical instrumentation and the design frameworks and tools that are adopted when specifying and implementing this category of instrumentation for improved process control.

The learning objectives of this module are that you will be able to explain:

Module: 040

High Performance Sensors

This module aims to give you an introduction to high performance sensors and

specialized technologies/systems for measurement.

The learning objectives of this module are that you will be able to explain:

Module: 050

Valve Actuation

This module aims to give you an introduction to the types of valve actuation as well as various types of valves used for automated control.

The learning objectives of this module are that you will be able to explain:

Module: 060

Motor and Drive Control

This module aims to give you an introduction to motor and drive control.

The learning objectives of this module are that you will be able to explain:

Module: 070

Electrical Planning and Installation

This module aims to give you an introduction to electrical installations.

The learning objective of this module is that you will be able to explain:

Section C: Control (Modules 080-170)

Module: 080

Continuous and Process Control

Module: 090

Discrete and Sequencing Control

This module aims to give you a clear understanding of discrete and sequencing control.

The learning objectives of this module are that you will be able to explain:

Module: 100

Batch Control

This module aims to give you a clear understanding of the concepts behind batch control. The learning objectives of this module are that you will be able to explain:

Module: 110

Building Automation Systems and HVAC

This module aims to give you a clear understanding of the basics of Building Automation Systems (BAS) – including Heating, Ventilation, Air Conditioning (HVAC) for the Life Sciences industry with a focus on the regulatory requirements using design examples. The learning objectives of this module are that you will be able to explain:

Module: 120

Motion Control

This module aims to give you a clear understanding of the concepts behind motion control.

The learning objectives of this module are that you will be able to explain:

Module: 130

Control Systems Types and Architecture

This module aims to introduce you to different control system types and the various architectures, hardware, and communication protocols used to implement them.

The learning objectives of this module are that you will be able to recognize the features and discuss the benefits of each of the following:

Module: 140

Documentation for Automation Engineering

This module aims to introduce you to control system documentation and the significance of different document types used to ensure project success.

The learning objectives of this module are that you will be able to explain:

Module: 150

Industrial Robotics

This module aims to give you a clear understanding of the concepts behind industrial robotics.

The learning objectives of this module are that you will be able to explain:

There are 2 performance objectives for this module:

Module: 160

Programming Languages for Automation Systems

This module aims to give you a clear understanding of automation programming languages.

The learning objectives of this module are that you will be able to:

– Ladder Diagram (LD)

– Function Block Diagram (FBD)

– Sequential Function Chart (SFC)

– Instruction List (IL)

– Structured Text (ST)

Module: 170

Visualization and Display

This module aims to give you a clear understanding of the concepts relating to the visualization of automated processes, best practices relating to the design of Human Machine Interfaces (HMIs), and the life-cycle management of such interfaces.

The learning objectives of this module are that you will be able to explain:

Section D: Communication, Integration, and Software (Modules 180-240)

Module: 180

Network Configuration Principles

This module aims to give you a clear understanding of the principles behind industrial networks and network configuration.

The learning objectives of this module are that you will be able to explain:

Module: 190

Introduction to Industrial Digital Field Protocols

This module aims to give you a clear understanding of the principles behind industrial digital field protocols and the implementation of these communication protocols between field equipment, digital controllers, and various software suites.

The learning objectives of this module are that you will be able to explain:

Module: 200

Overview of Industrial Communication Protocols

This module aims to give you a clear understanding of the principles behind industrial digital field protocols used to link process control and plant automation modules.

The learning objectives of this module are that you will be able to explain:

Module: 210

Introduction to Manufacturing Operations Management

This module aims to introduce you to the concepts behind Manufacturing Operations Management (MOM) and how it relates to other concepts such as digital thread, digital twin, and Manufacturing Execution Systems.

The learning objectives of this module are that you will be able to define or describe:

Module: 220

Introduction to Manufacturing

Execution Systems

This module aims to introduce you to Manufacturing Execution Systems and how decisions are made regarding which systems should be governed by the control domain (i.e. Production and Operations) or the enterprise domain (i.e. Business).

The learning objectives of this module are that you will be able to explain:

Module: 230

Database Management

This module aims to give you an overview of the concepts relating to databases and database management.

The learning objectives of this module are that you will be able to explain:

Module: 240

Introduction to Historian Software Platforms

This module aims to give you a clear understanding of the purpose of historian software as well as examples of what historian software vendors offer.

The learning objectives of this module are that you will be able to explain:

Section E: Automation System Safety and Reliability (Modules 250-300)

Module: 250

Alarm Management

This module aims to give you a clear understanding of the concepts relating to alarm system management.

The learning objectives of this module are that you will be able to explain:

After this module you should be able to analyze and determine the need for design changes or additional equipment to improve safety with regards to the following:

Module: 260

Reliability

This module aims to give you a clear understanding of the concepts behind reliability.

The learning objectives of this module are that you will be able to explain:

Module: 270

Machine and Process Guarding

This module aims to give you a clear understanding of the concepts behind machine and process guarding.

The learning objectives of this module are that you will be able to explain machine and process guarding in terms of:

Module: 280

Manufacturing Safety

This module aims to give you a clear understanding of the concepts relating to manufacturing safety in general.

The learning objectives of this module are that you will be able to explain:

Module: 290

Safety Controller Equipment and Safety Standards

This module aims to give you a clear understanding of the concepts behind safety controller equipment as well as key safety standards and best practices.

The learning objectives of this module are that you will be able to understand

Module: 300

Good Automated Manufacturing Practice

This module aims to give you a clear understanding of the concepts and benefits of Good Automated Manufacturing Practice, or GAMP for short.

The learning objectives of this module are that you will be able to:

Section F: Industrial Control Systems Cybersecurity (Modules 310-370)

Module: 310

Introduction to Manufacturing Cybersecurity

This module aims to give you a clear understanding of the concepts behind cybersecurity, with a focus on Industrial cybersecurity.

The learning objectives of this module are that you will be able to explain:

Module: 320

Operational Technology Architectures

This module aims to give you a clear understanding of the concepts behind Operational Technology (OT) and OT architectures.

The learning objectives of this module are that you will be able to explain:

Module: 330

Networks

This module aims to give you a clear understanding of the concepts behind Networks, with a focus on Industrial cyber security.

The learning objectives of this module are that you will be able to explain:

Module: 340

Operating Systems

This module aims to give you a clear understanding of the concepts behind Operating Systems with a focus on Industrial cyber security.

The learning objectives of this module are that you will be able to explain:

Module: 350

Telecommunications

This module aims to give you a clear understanding of concepts behind telecommunications and data transmission.

The learning objectives of this module are that you will be able to explain:

Module: 360

Information Assurance

This module aims to give you a clear understanding of concepts behind information

assurance.

The learning objectives of this module are that you will be able to explain:

Module: 370

The Security Lifecycle

This module aims to give you a clear understanding of concepts behind the NIST

Cyber Security Framework in relation to providing a common language to the Cyber Security lifecycle.

The learning objectives of this module are that you will be able to explain:

WHAT CURRENT PARTICIPANTS ARE SAYING ABOUT THIS COURSE

“What I am learning at the beginning of the program is really helping me understand the holistic approach of automation, and gain the understanding that it’s not just manufacturing, but also analytics, supply chain, and many other aspects of the drug development process. The course so far has been a lot of review for me as an automation person, but it is also very helpful and a good teaching tool for new analysts, giving them an understanding of what automation is.”

- Rich Smart, Scientist at Biogen

“I personally benefitted greatly from the IAAE learning modules. I actually started working as a contractor with Castle Hill Technologies working on a project in security. Just going through these learning modules over the summer really helped me get up to speed and speak the same language as my boss. Some of the terminology I did not know coming into my work has been taught through these modules.”

- Albert Shin, currently pursuing a Master’s in Biomanufacturing at NCSU and IAAE® Student Advisory Council Member

IAAE seeks to credential 10,000 learners globally, and to engage 10 of the top 20 companies in each regulated health industry, by the end of 2035.

© 2023 International Academy of Automation Engineering