Course 1

Essentials of automation for manufacturing

37 Modules | 3 hours per module

This course was developed by automation experts who work in the Life Sciences industry, was reviewed by SMEs from Merck, Genentech, as well as our academic partners, and links to the Automation Competency Model by the Automation Federation.

This course offers

- Access from any device

- Certificate of completion

- 3 hours online course content per module ( 37 modules)

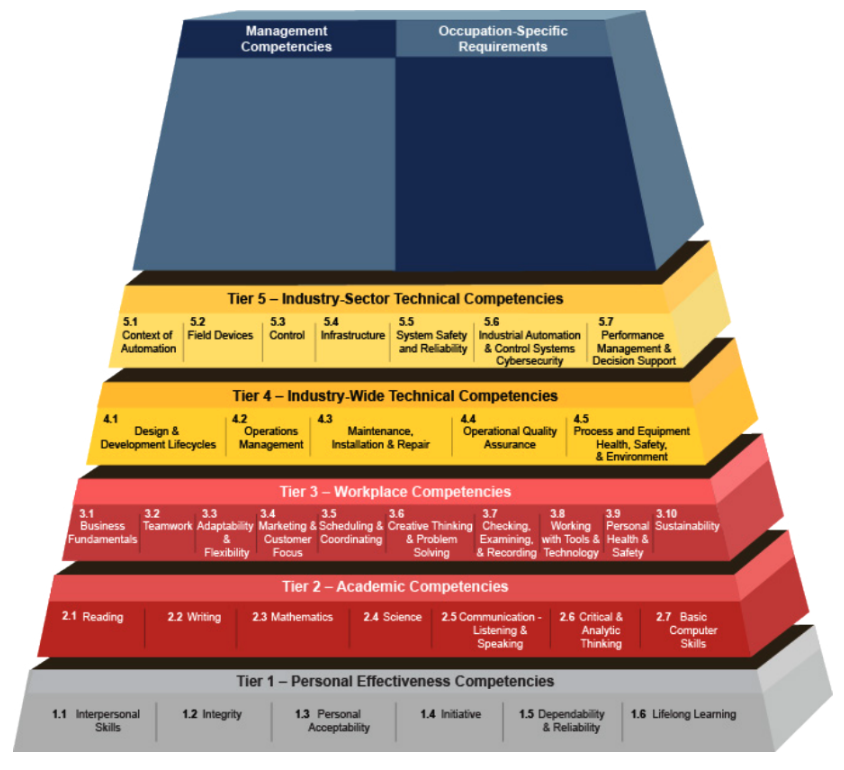

The Automation Competency Model is a resource that provides a comprehensive collection of the competencies – the knowledge, skills, and abilities – required in the automation industry. The competencies are described using examples of the critical work functions and the technical content common to the industry. A competency describes a behavior but does not describe a level of performance, as different workers will need different levels of competence to complete their job functions.

The model is depicted in a graphic consisting of several tiers. Each tier is comprised of blocks that group the knowledge, skills, and abilities essential for successful performance in the industry. At the base of the model, the competencies apply to a large number of occupations and industries. As a user moves up the model, the competencies become industry- and occupation-specific. The pyramid shape does not imply that competencies at the top are at a higher level of skill. Instead, the model’s shape represents the increasing specialization and specificity in the application of skills.

Tiers 1 through 3, called Foundation Competencies, form the foundation needed to be ready to enter the workplace.

Tier 1 – Personal Effectiveness Competencies represent personal attributes or “soft skills”. Essential for all life roles, personal effectiveness competencies are generally learned in the home or community and reinforced at school and in the workplace.

Tier 2 – Academic Competencies are critical competencies primarily learned in a school setting. They include cognitive functions and thinking styles, and are likely to apply to most industries and occupations.

Tier 3 – Workplace Competencies represent motives and traits, as well as interpersonal and self-management styles honed in the workplace. They are generally applicable to a large number of occupations and industries.

Tiers 4 and 5 show the cross-cutting industry-wide technical competencies needed within an industry wherein a worker can move easily across industry sub-sectors. Rather than narrowly defining a single occupational career ladder, this model supports the development of an agile workforce.

Tier 4 – General Technical Competencies represent the basic knowledge and skills that are common across automation sectors.

Tier 5 – Specific Technical Competencies represent advanced competencies that are specific to automation. The upper tiers represent the occupational specialization within the industry.

Module: 010 | Introduction to automation for Life Sciences manufacturing

This introductory module aims to introduce you to automation for Life Sciences manufacturing by asking:

- What is the Life Sciences industry?

- What is automation?

- What is automation for Life Sciences manufacturing?

- What standards relate to automation systems design and operation?

- What is the future of automation for Life Sciences manufacturing?

Module: 010 Introduction to automation for Life Sciences manufacturing

Module: 020 | Basic Process Instrumentation

This module aims to give you an introduction to measurement and basic process instrumentation. The learning objectives of this module are that you will be able to explain measurement of: Flow, Temperature, Pressure, Level

Module: 030 | Analytical Instrumentation

This module aims to give you an introduction to the purpose of analytical instrumentation and the design frameworks and tools that are adopted when specifying and implementing this category of instrumentation for improved process control.

The learning objectives of this module are that you will be able to explain:

- the Quality by Design (QbD) process

- the analyzer sampling type process

- the analytical instrument technology selection process

- the steps in choosing and installing a sample conditioning system

- the importance of maintaining analytical instruments and analyzers

- at a high level what a Process Analytical Technologies framework is

Module: 040 | High Performance Sensors

This module aims to give you an introduction to high performance sensors and

specialized technologies/systems for measurement.

The learning objectives of this module are that you will be able to explain:

- Some of the application needs for high performance sensors

- Auto-identification

- Vision systems

Module: 050 | Valve Actuation

This module aims to give you an introduction to the types of valve actuation as well as various types of valves used for automated control.

The learning objectives of this module are that you will be able to explain:

- The purpose of actuation

- Electric actuation

- Hydraulic actuation

- Pneumatic actuation

- A variety of valve types

Module: 060 | Motor and Drive Control

This module aims to give you an introduction to motor and drive control.

The learning objectives of this module are that you will be able to explain:

- Concepts of motor and electronic drive control

Module: 070 | Electrical Planning and Installation

This module aims to give you an introduction to electrical installations.

The learning objective of this module is that you will be able to explain:

- The electrical installation requirements for an automated manufacturing plant

Module: 080 | Continuous and Process Control

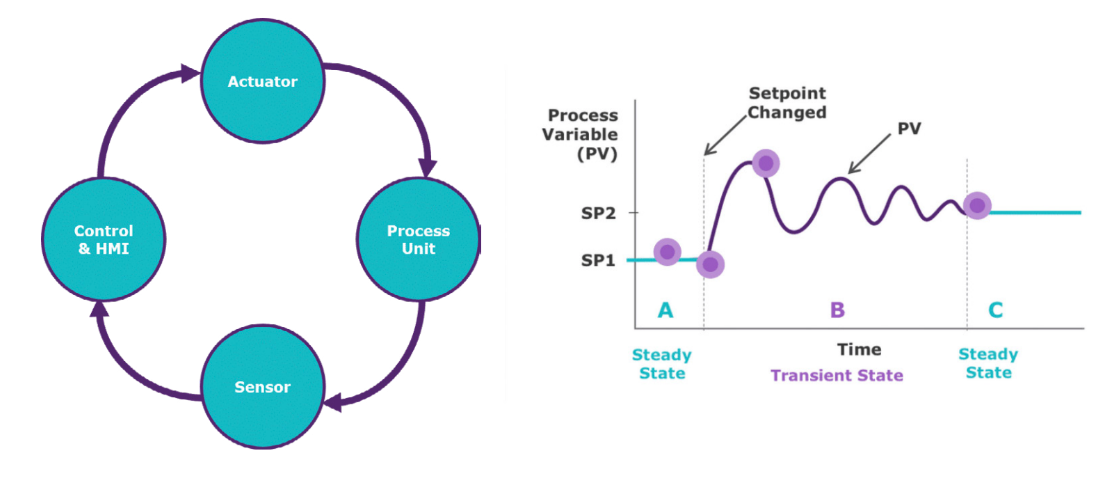

This module aims to give you a clear understanding of continuous process control. The learning objectives of this module are that you will be able to explain: Continuous process characteristics, Feedback control & what loop tuning is, The principles of advanced regulatory control

Module: 090 | Discrete and Sequencing Control

This module aims to give you a clear understanding of discrete and sequencing control.

The learning objectives of this module are that you will be able to explain:

- The concepts behind discrete/sequential control

- The basic functional structure of a Programmable Logic Controller

- Some of the textual and graphical languages used to program automated systems

Module: 100 | Batch Control

This module aims to give you a clear understanding of the concepts behind batch control. The learning objectives of this module are that you will be able to explain:

- batch process and batch processing configurations

- types of batch control, including basic control, procedural control and coordination control

- batch control and the S88 Standard

- different types of batch recipes and the information required in a recipe

Module: 110 | Building Automation Systems and HVAC

This module aims to give you a clear understanding of the basics of Building Automation Systems (BAS) – including Heating, Ventilation, Air Conditioning (HVAC) for the Life Sciences industry with a focus on the regulatory requirements using design examples. The learning objectives of this module are that you will be able to explain:

- The different design requirements for office spaces and mission critical spaces such as spaces for manufacturing, lab, and warehouse, which may be called Good Manufacturing Practice (GMP) spaces

- HVAC equipment

- BAS architectures and components

- HVAC/BAS project lifecycle

- Popular BAS vendors and products

Module: 120 | Motion Control

This module aims to give you a clear understanding of the concepts behind motion control.

The learning objectives of this module are that you will be able to explain:

- the different types of motion control used to automate machine and processes

- some basic steps to follow when designing motion control systems

Module: 130 | Control Systems Types and Architecture

This module aims to introduce you to different control system types and the various architectures, hardware, and communication protocols used to implement them.

The learning objectives of this module are that you will be able to recognize the features and discuss the benefits of each of the following:

- Distributed Control System (DCS)

- Process Automation System (PAS)

- Programmable Automation Controller (PAC)

- Programmable Logic Controller (PLC)

- Supervisory Control and Data Acquisition (SCADA)

- Embedded Systems

Module: 140 | Documentation for Automation Engineering

This module aims to introduce you to control system documentation and the significance of different document types used to ensure project success.

The learning objectives of this module are that you will be able to explain:

- The need for a variety of documentation types needed to support the life-cycle of automation projects.

- The value of documentation to capture project information as well as communicate information between team members.

- Understand the benefit and intended use of each main document type.

Module: 150 | Industrial Robotics

This module aims to give you a clear understanding of the concepts behind industrial robotics.

The learning objectives of this module are that you will be able to explain:

- How robots are utilized in industrial applications

There are 2 performance objectives for this module:

- Demonstrate an understanding of the variety of applications for industrial robotics

- Research and make a recommendation for a suitable industrial robot for a set of stated requirements

Module: 160 | Programming Languages for Automation Systems

This module aims to give you a clear understanding of automation programming languages.

The learning objectives of this module are that you will be able to:

- Explain the purpose of the IEC 61133-3 standard

- Identify each of the programming languages defined:

- Ladder Diagram (LD)

- Function Block Diagram (FBD)

- Sequential Function Chart (SFC)

- Instruction List (IL)

- Structured Text (ST)

- Discuss key features of each language

- Explain future trends in programming

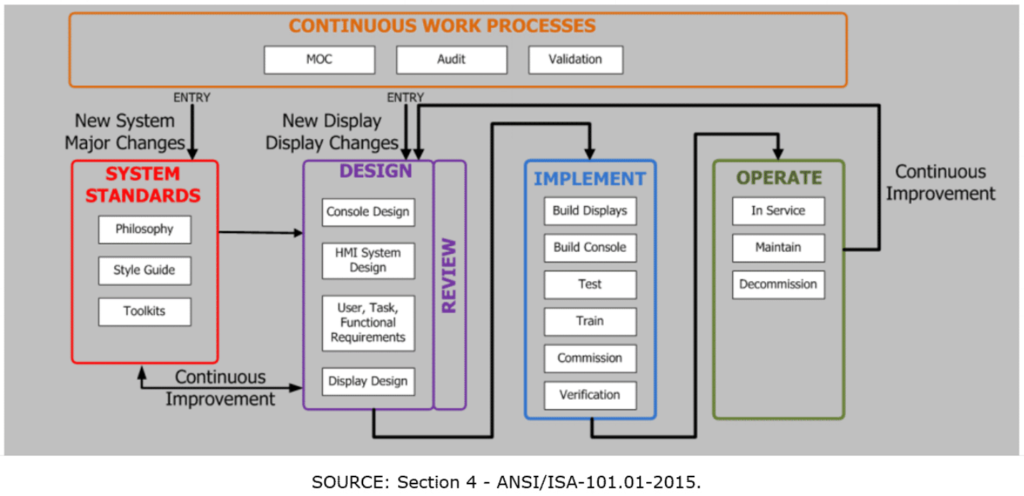

Module: 170 | Visualization and Display

This module aims to give you a clear understanding of the concepts relating to the visualization of automated processes, best practices relating to the design of Human Machine Interfaces (HMIs), and the life-cycle management of such interfaces.

The learning objectives of this module are that you will be able to explain:

- the purpose of Human Machine Interfaces (HMIs)

- why certain HMI interfaces are far better than others

- the basics of human factors engineering & ergonomics relating to situational awareness and sensory limits

- how HMI applications are evaluated in terms of display styles and performance factors

- HMI system management and lifecycle stages

Module: 180 | Network Configuration Principles

This module aims to give you a clear understanding of the principles behind industrial networks and network configuration.

The learning objectives of this module are that you will be able to explain:

- the benefits of both cable and wireless networks

- network component configuration

- network diagnostics and network management

Module: 190 | Introduction to Industrial Digital Field Protocols

This module aims to give you a clear understanding of the principles behind industrial digital field protocols and the implementation of these communication protocols between field equipment, digital controllers, and various software suites.

The learning objectives of this module are that you will be able to explain:

- Why digital field protocols are necessary for industry applications

- The main protocols used in industry such as Foundation Fieldbus, HART, Profibus, and Ethernet/IP.

Module: 200 | Overview of Industrial Communication Protocols

This module aims to give you a clear understanding of the principles behind industrial digital field protocols used to link process control and plant automation modules.

The learning objectives of this module are that you will be able to explain:

- why industrial communication protocols are necessary for industry applications

- the main protocols used in industry such as BACnet, LonWorks, OPC, and Ethernet TCP/IP

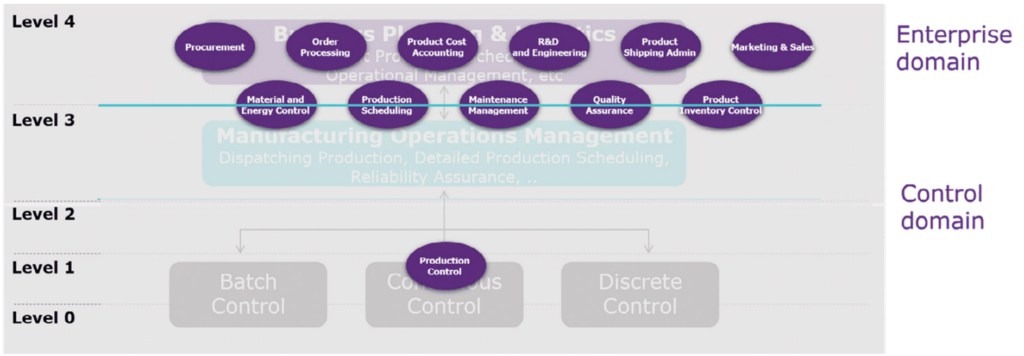

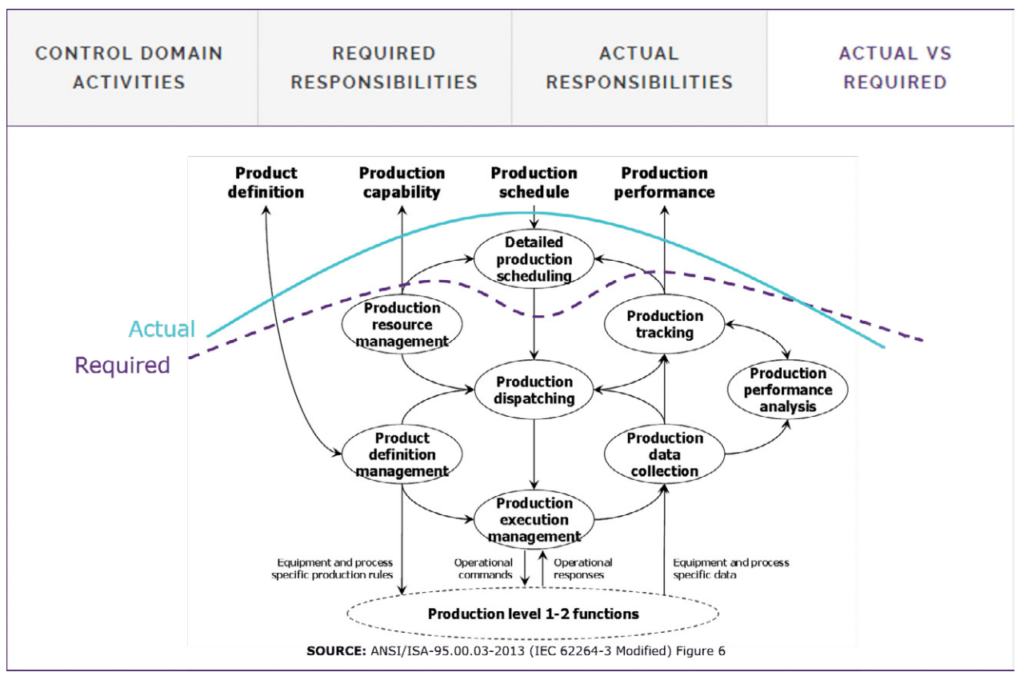

Module: 210 | Introduction to Manufacturing Operations Management

This module aims to introduce you to the concepts behind Manufacturing Operations Management (MOM) and how it relates to other concepts such as digital thread, digital twin, and Manufacturing Execution Systems.

The learning objectives of this module are that you will be able to define or describe:

- Manufacturing Operations Management activities

- The typical business drivers for integration of systems

- The six parts of the International Society of Automation (ISA) ISA-95 standard

- The level 3-4 boundaries and information flows

- Manufacturing Operations Functions

- Information flows from the enterprise domain functions to the control domain functions and vice versa

Module: 220 | Introduction to Manufacturing Execution Systems

This module aims to introduce you to Manufacturing Execution Systems and how decisions are made regarding which systems should be governed by the control domain (i.e. Production and Operations) or the enterprise domain (i.e. Business).

The learning objectives of this module are that you will be able to explain:

- the variety of computer systems used for manufacturing

- how control responsibility can be defined

- sample lines of technical integration (ie. how systems will be implemented along boundary lines)

- what typical MES vendors have to offer

- enterprise asset management

Module: 230 | Database Management

This module aims to give you an overview of the concepts relating to databases and database management.

The learning objectives of this module are that you will be able to explain:

- key advantages of a Database Management System (DBMS)

- the need for data security and data quality

- the basic principles of designing databases

- interacting with databases to run and generate reports

- special requirements of real-time databases

- key activities to maintain databases

Module: 240 | Introduction to Historian Software Platforms

This module aims to give you a clear understanding of the purpose of historian software as well as examples of what historian software vendors offer.

The learning objectives of this module are that you will be able to explain:

- the purpose of historian software

- the typical sources of data for a historian

- a number of example historian solutions available in the market

Module: 250 | Alarm Management

This module aims to give you a clear understanding of the concepts relating to alarm system management.

The learning objectives of this module are that you will be able to explain:

- Alarm system management

- HMI design and performance metrics as they relate to alarm systems

After this module you should be able to analyze and determine the need for design changes or additional equipment to improve safety with regards to the following:

- Alarm prioritization

- Performance metrics

- HMI design

Module: 260 | Reliability

This module aims to give you a clear understanding of the concepts behind reliability.

The learning objectives of this module are that you will be able to explain:

- Measurements of successful operation

- Dangerous and safe failure modes

- Types of redundancy

Module: 270 | Machine and Process Guarding

This module aims to give you a clear understanding of the concepts behind machine and process guarding.

The learning objectives of this module are that you will be able to explain machine and process guarding in terms of:

- design considerations

- laws and regulations

- protection levels

- risk analysis

Module: 280 | Manufacturing Safety

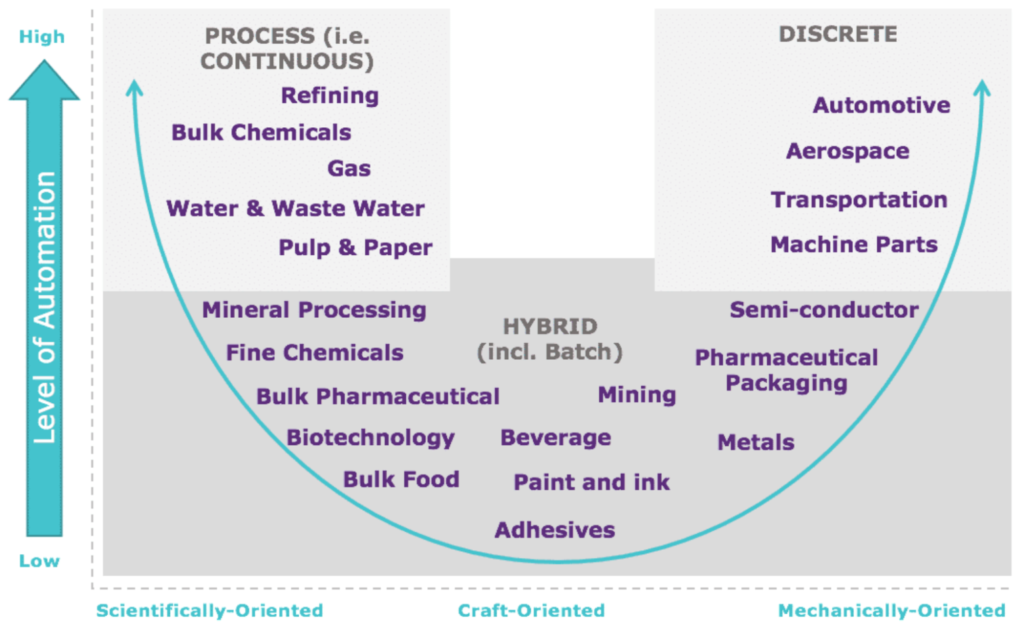

This module aims to give you a clear understanding of the concepts relating to manufacturing safety in general.

The learning objectives of this module are that you will be able to explain:

- manufacturing safety for process, discrete, and hybrid processes

- hazard and risk analysis

- the activities carried out in the safety life cycle

Module: 290 | Safety Controller Equipment and Safety Standards

This module aims to give you a clear understanding of the concepts behind safety controller equipment as well as key safety standards and best practices.

The learning objectives of this module are that you will be able to understand

- the purpose of Safety PLCs and Safety Instrumented Systems (SIS)

- equipment for use where explosive concentrations might be present

- installation design for hazardous areas

- some OSHA, IEC and ISO safety standards

Module: 300 | Good Automated Manufacturing Practice

This module aims to give you a clear understanding of the concepts and benefits of Good Automated Manufacturing Practice, or GAMP for short.

The learning objectives of this module are that you will be able to:

- list some of the key drivers for GAMP 5

- define Life cycle phases and use of a general project model

- explain how GAMP supports Quality Risk Management

- discuss regulated company activities

- recognize supplier activities

- explain the GAMP Validation Model approach for a Configured Product (Note: The GAMP V Model should not to be confused with GAMP 5)

• understand the GAMP V Model approach for a Custom Application

Module: 310 | Introduction to Manufacturing Cybersecurity

This module aims to give you a clear understanding of the concepts behind cybersecurity, with a focus on Industrial cybersecurity.

The learning objectives of this module are that you will be able to explain:

- cybersecurity strategies including CIA Triad, Defense in Depth, Principle of Least

Privilege, and the User. - the relevant Policies and Procedures in Information Technology (IT) & Operational

Technology (OT). - the security life-cycle, defining the different stages.

- how the human factor influences cybersecurity strategies.

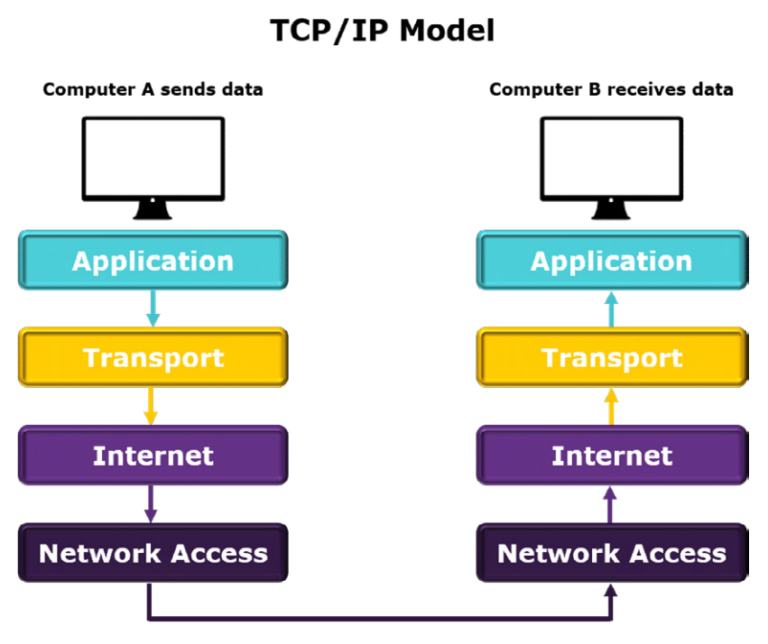

Module: 320 | Operational Technology Architectures

This module aims to give you a clear understanding of the concepts behind Operational Technology (OT) and OT architectures.

The learning objectives of this module are that you will be able to explain:

- typical OT architecture, considering the Purdue model and ISA-95 Level definitions

- the layers of operation of communication protocols, comparing the ISO model with the TCP/IP model

- what the drivers of OT systems are

Module: 330 | Networks

This module aims to give you a clear understanding of the concepts behind Networks, with a focus on Industrial cyber security.

The learning objectives of this module are that you will be able to explain:

- Introduction to Industrial Networks

- Separation of OT and IT network components

- Zones, Conduits and Security levels

Module: 340 | Operating Systems

This module aims to give you a clear understanding of the concepts behind Operating Systems with a focus on Industrial cyber security.

The learning objectives of this module are that you will be able to explain:

- Operating systems

- Patch management

Module: 350 | Telecommunications

This module aims to give you a clear understanding of concepts behind telecommunications and data transmission.

The learning objectives of this module are that you will be able to explain:

- Data transmission media

- Serial and Parallel Data Transmission

- Asynchronous and Synchronous Data Transmission

- Rates of Data Transmission

- Modes of Data Transmission including Simplex, Half Duplex, and Full Duplex

- Bus Properties, Uses, and Types

Module: 360 | Information Assurance

This module aims to give you a clear understanding of concepts behind information

assurance.

The learning objectives of this module are that you will be able to explain:

- Identity management and Access Control.

- The three elements of the CIA triad: Data Integrity, Data Confidentiality and Resource Availability.

- The basic operation of event management

Module: 370 | The Security Lifecycle

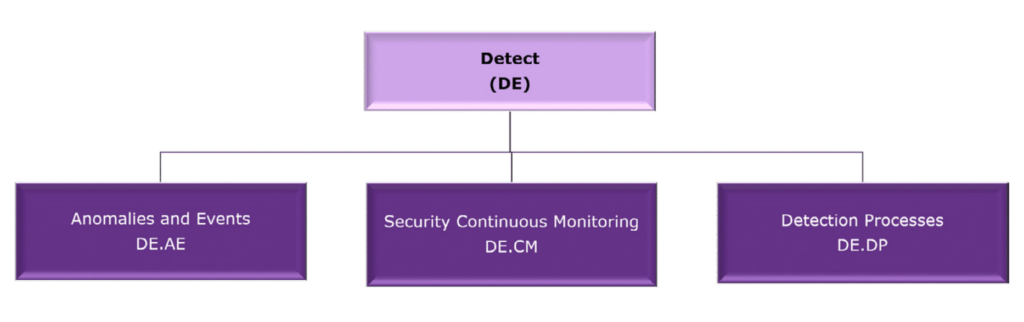

This module aims to give you a clear understanding of concepts behind the NIST

Cyber Security Framework in relation to providing a common language to the Cyber Security lifecycle.

The learning objectives of this module are that you will be able to explain:

- The NIST Framework key elements- Core, Profile, and Implementation tiers

- The five Functions of the NIST Framework

- The structure of the Framework core

- The most commonly used Informative References of the NIST Framework