Course 1C

Control

10 Modules | 30 hours

This course section covers various modules related to different aspects of automation control systems. These modules include continuous process control, discrete and sequencing control, batch control, building automation systems, motion control, control system types, documentation, industrial robotics, automation programming languages, and visualization of automated processes. Each module has specific learning objectives, and the course aims to provide a comprehensive understanding of automation control systems. Topics covered include control system architectures, programming languages, visualization, and life-cycle management.

This course offers

- Access from any device

- Certificate of completion

- 30 hours online course content

Module: 080 | Continuous and Process Control

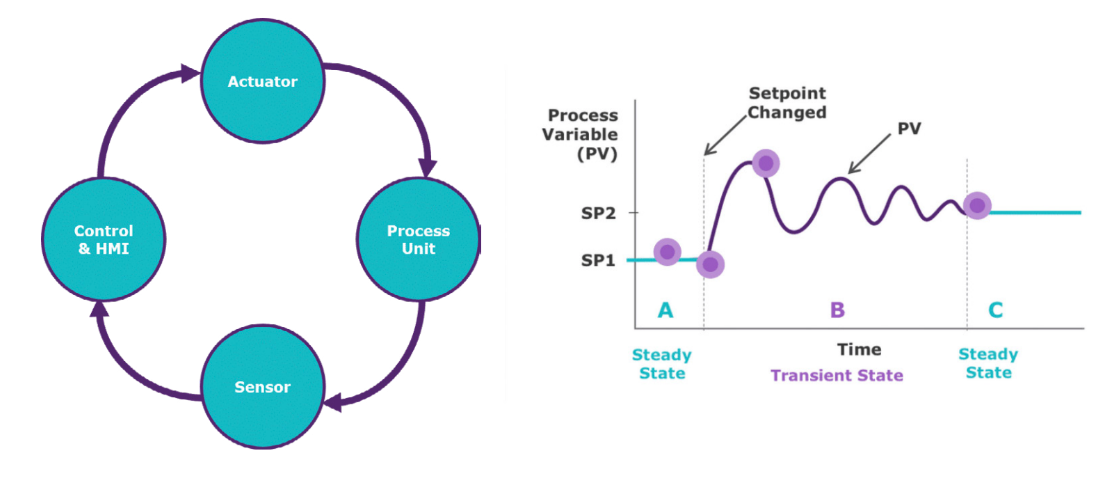

This module aims to give you a clear understanding of continuous process control. The learning objectives of this module are that you will be able to explain: Continuous process characteristics, Feedback control & what loop tuning is, The principles of advanced regulatory control

Module: 90 | Discrete and Sequencing Control

This module aims to give you a clear understanding

of discrete and sequencing control.

The learning objectives of this module are that you will be able to explain:

- The concepts behind discrete/sequential control

- The basic functional structure of a Programmable Logic Controller

- Some of the textual and graphical languages used to program automated systems

Module: 100 | Batch Control

This module aims to give you a clear understanding of the concepts behind batch control

The learning objectives of this module are that you will be able to explain:

- batch process and batch processing configurations

- types of batch control, including basic control, procedural control and coordination control

- batch control and the S88 Standard

- different types of batch recipes and the information required in a recipe

Module: 110 | Building Automation Systems and HVAC

This module aims to give you a clear understanding of the basics of Building Automation Systems (BAS) – including Heating, Ventilation, Air Conditioning (HVAC) for the Life Sciences industry with a focus on the regulatory requirements using design examples.

The learning objectives of this module are that you will be able to explain:

- The different design requirements for office spaces and mission critical spaces such as spaces for manufacturing, lab, and warehouse, which may be called Good Manufacturing Practice (GMP) spaces

- HVAC equipment

- BAS architectures and components

- HVAC/BAS project lifecycle

- Popular BAS vendors and products

Module: 120 | Motion Control

This module aims to give you a clear understanding of the concepts behind motion control.

The learning objectives of this module are that you will be able to explain:

- the different types of motion control used to automate machine and processes

- some basic steps to follow when designing motion control systems

Module: 130 | Control Systems Types and Architecture

This module aims to introduce you to different control system types and the various architectures, hardware, and communication protocols used to implement them.

The learning objectives of this module are that you will be able to recognize the features and discuss the benefits of each of the following:

- Distributed Control System (DCS)

- Process Automation System (PAS)

- Programmable Automation Controller (PAC)

- Programmable Logic Controller (PLC)

- Supervisory Control and Data Acquisition (SCADA)

- Embedded Systems

Module: 140 | Documentation for Automation Engineering

This module aims to introduce you to control system documentation and the significance of different document types used to ensure project success.

The learning objectives of this module are that you will be able to explain:

- The need for a variety of documentation types needed to support the life-cycle of automation projects.

- The value of documentation to capture project information as well as communicate information between team members.

- Understand the benefit and intended use of each main document type.

Module: 150 | Industrial Robotics

This module aims to give you a clear understanding of the concepts behind industrial robotics.

The learning objectives of this module are that you will be able to explain:

- How robots are utilized in industrial applications

There are 2 performance objectives for this module:

- Demonstrate an understanding of the variety of applications for industrial robotics

- Research and make a recommendation for a suitable industrial robot for a set of stated requirements

Module: 160 | Programming Languages for Automation Systems

This module aims to give you a clear understanding of automation programming languages.

The learning objectives of this module are that you will be able to:

- Explain the purpose of the IEC 61133-3 standard

- Identify each of the programming languages defined:

- Ladder Diagram (LD)

- Function Block Diagram (FBD)

- Sequential Function Chart (SFC)

- Instruction List (IL)

- Structured Text (ST)

- Discuss key features of each language

- Explain future trends in programming

Module: 170 | Visualization and Display

This module aims to give you a clear understanding of the concepts relating to the visualization of automated processes, best practices relating to the design of Human Machine Interfaces (HMIs), and the life-cycle management of such interfaces.

The learning objectives of this module are that you will be able to explain:

- the purpose of Human Machine Interfaces (HMIs)

- why certain HMI interfaces are far better than others

- the basics of human factors engineering & ergonomics relating to situational awareness and sensory limits

- how HMI applications are evaluated in terms of display styles and performance factors

- HMI system management and lifecycle stages